Production

At the forefront of irrigation systems

for over 50 years.

Rain has always put innovation at the heart of its irrigation system production. It is no coincidence that research and development has been internal to the company since its foundation. The development and registration of patents is an integrable part of the production activity. This has grown over time, always following precise guidelines.

The valorisation of resources, to save time for the professional installer and make life easier for the private user. The valorisation of the environment, through the use of renewable energy and saving water. Finally, the valorisation of customers through prompt communication and efficient service.

of manufacturing experience

energy consumption per unit in 5 years

energy from renewable sources

of the material used is of recycled origin (7% internal self-recycling)

average age of injection moulding machines

Testing and Warehousing

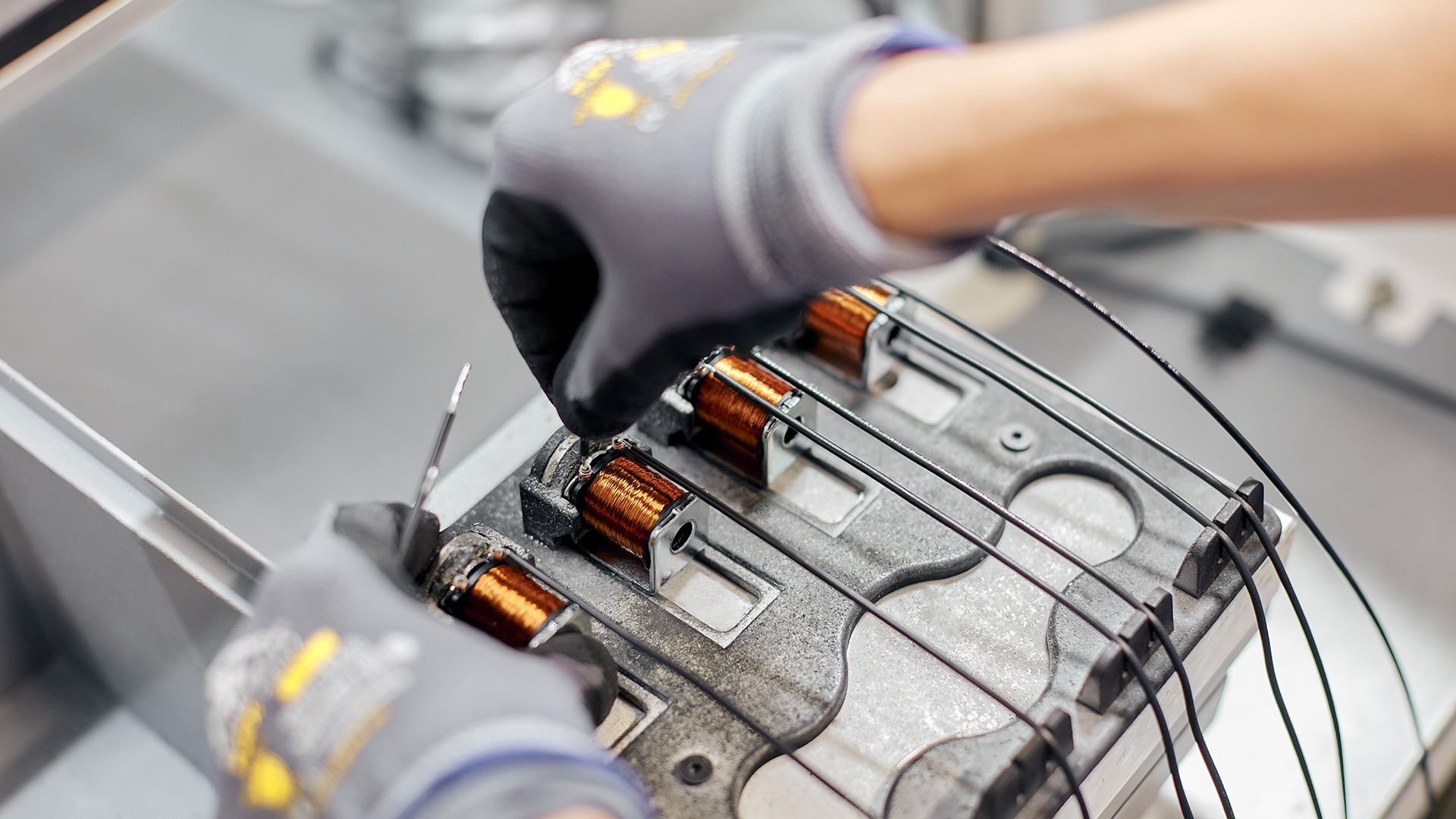

Product testing is of particular importance in our production chain. As a specific example, our solenoid valves are individually tested one by one. But we give just as much weight to logistical efficiency, with a highly automated vertical warehouse that enables fast and accurate shipments: over 15,000 per year.

In the Italian market, our agents take orders on tablets, transmit them directly to the warehouse and start shipping within just 12 hours. Our geographical location also enhances and benefits our work: we are located in the heart of Europe, in a strategic area well served by motorways and airports.

Quality of work, quality of product

For Rain, the quality of the environment and working conditions is directly reflected in the quality of the product. Therefore, we make sure that our employees always work under the best conditions, in every department. And the results are clear to see: this is demonstrated by the very low turnover of our highly specialised assembly personnel.

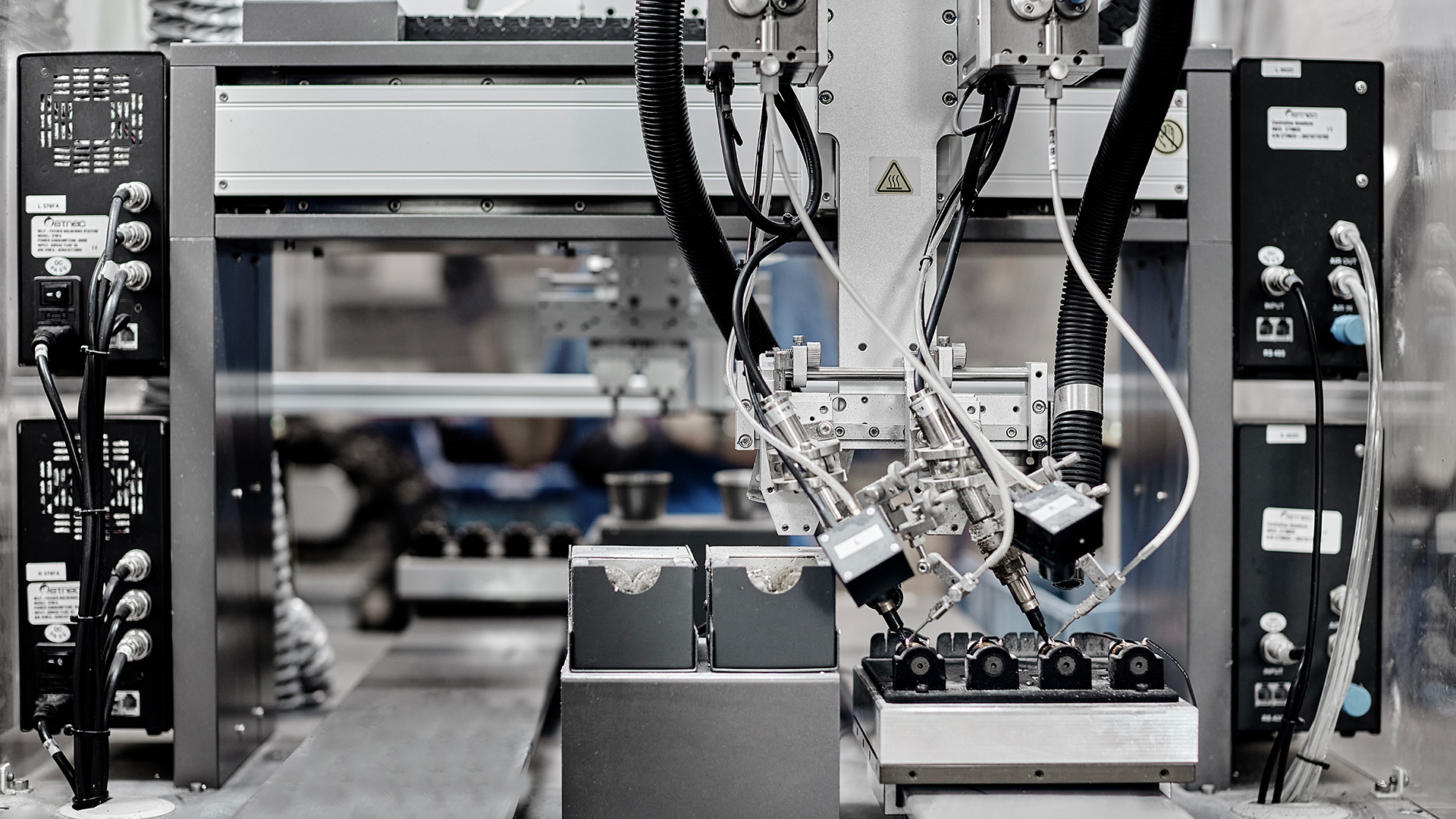

Production process 4.0 and digitised quality control

The 4.0 production process, i.e. highly digitised, allows us to achieve a close interconnection between customer demand and the production result. It is a constant and totally computerised dialogue: no paper forms, but absolute quality and punctuality throughout the entire supply chain visible on the production machinery’s tablet screens.

Entire solenoid valve production process in-house

For 40 years the entire production process has been in-house, from design to production, especially that of our solenoid valves. But the solenoid valves, valve boxes and all the components inside are almost totally self-produced. The aim is always the continuous improvement of the products, both from a design and functional point of view, to make installation quick for the professional and easier for the private customer.

Product traceability for absolute quality.

Constant traceability, during and after production, is a precise guarantee of quality for us. Our solenoid valves and control units are in fact tracked not by batch but by product number, i.e. one by one. This is a precise quality choice, which facilitates after-sales service and guarantees each individual product.

Gallery

Contact us

to find out more.